With fabricated/stacked chips, our experts help our customers in the fabricated/stacked chip industry customize their product in ways traditional chips could never be. From shape to flavor to color, each chip is identical, which allows for unique packaging options. Our fabricated/stacked chips processing equipment gives you minute and consistent control while processing your snack products.

Conveyors are fast, efficient mechanical handling apparatuses that transport materials from point A to point B and play a critical role in advancing industry.

Read more

From live equipment demonstrations to in-depth conversations about the future of food processing, FoodTech Forum 2025 created a unique space for exploring what’s next. Over three dynamic weeks, Heat and Control® welcomed customers, strategic partners, and industry experts to share ideas and to explore practical solutions for sustainable food processing.

Read more

The growing market for nutraceuticals and functional foods leads to additional challenges for metal detection which can be solved through the use of multi-spectrum technology.

Read more

The snack food market is one of the strongest markets in the food world and continues to increase due to several factors, including an increasing trend for global and non-traditional flavor options, an increasing demand for snacks among the millennial population, and the growth of mixed and blended products. However, operations teams are also faced with labor shortages, productivity needs, and accuracy requirements.

Read more

In 1972, Ishida revolutionized the packaging industry by inventing computer combination weighing (CCW) technology. Ishida, the biggest name in weighing technology, offers the ultimate performance and delivers the top performing multihead weighing machines so their customers’ products are handled gently, cleanly, and efficiently.

Read more

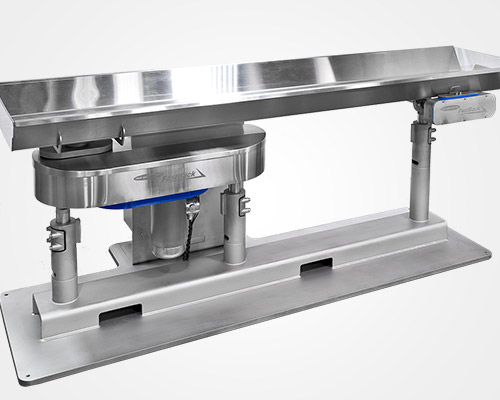

The FastBack® 4.0’s patented circular to linear motion design gently handles product so it is undamaged, and the coatings are undisturbed to provide the ultimate performance, flexibility, and highest travel rates and flow rate capacity in the industry.

Read more

Metal is one of the most commonly found contaminants in food and can be introduced at all stages of food manufacturing. By identifying metal contaminants during processing or packaging, a metal detector helps ensure the safety and the integrity of a wide range of unpackaged, packaged, or bulk goods and helps to eliminate metal contaminants from a food manufacturer’s finished product.

Read more

Checkweighers are designed to divert inferior product off the production line. Depending on a manufacturer’s product, Ishida provides several rejector arm options to optimize the checkweighing process.

Read more