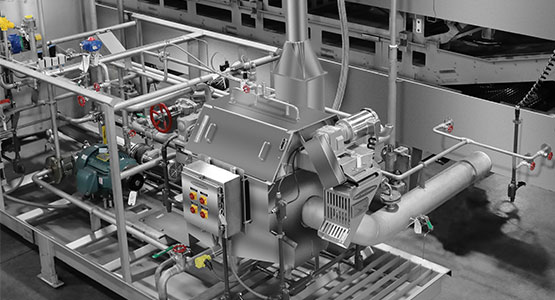

Oil Sweep® De-oiling System

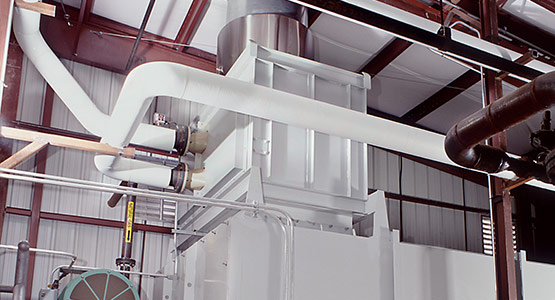

Strip fried potato products of surface-oil prior to freezing and packing. The stripped oil is recovered through a bank of cyclones and returned to the fryer oil recovery system. Solid fines are separated, and the reusable oil is transferred back into the frying system.