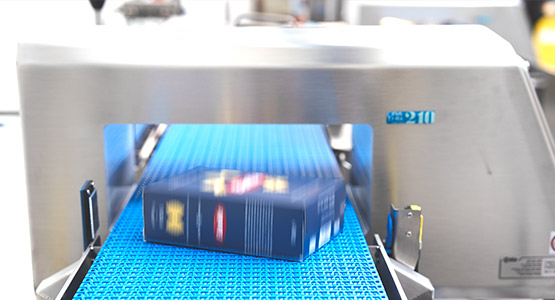

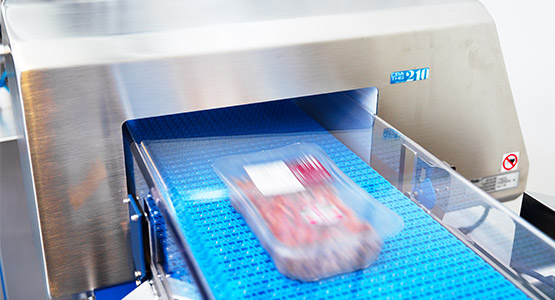

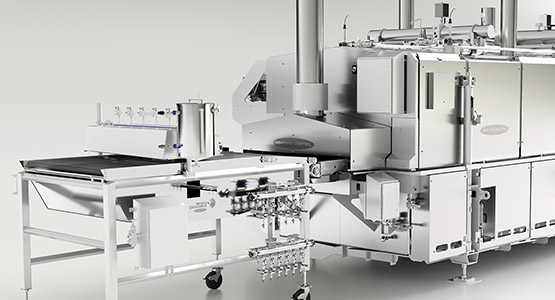

THS/210®-MBH5 Metal Detection System for Dry Food-Processing Areas

A next‑generation, fully digital metal detection system designed for dry food-processing environments, delivering high‑accuracy contaminant detection with robust construction compatible with low-pressure washdown and dust-prone environments.