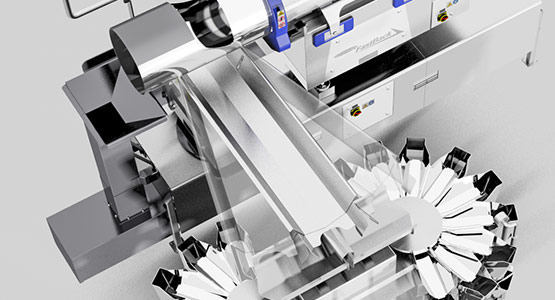

FastBack

FastBack 4.0 Horizontal Motion Conveyor

The patented circular to linear motion design gently handles the product so it is undamaged and the coatings are undisturbed, providing the ultimate performance and flexibility and the industry’s highest travel rates and flow rate capacity.