This article outlines five common mistakes that reduce frying oil life and provides practical strategies to help food manufacturers protect oil quality, improve operational efficiency, and achieve more sustainable, cost-effective frying operations.

Read more

Today’s snack manufacturers need packaging systems that can keep pace with rising demand for small‑bag and multi‑pack formats. Engineered for speed, accuracy, and efficiency, this high‑speed packaging solution delivers the performance modern lines require to stay competitive.

Read more

Conveyors are fast, efficient mechanical handling apparatuses that transport materials from point A to point B and play a critical role in advancing industry.

Read more

From live equipment demonstrations to in-depth conversations about the future of food processing, FoodTech Forum 2025 created a unique space for exploring what’s next. Over three dynamic weeks, Heat and Control® welcomed customers, strategic partners, and industry experts to share ideas and to explore practical solutions for sustainable food processing.

Read more

The growing market for nutraceuticals and functional foods leads to additional challenges for metal detection which can be solved through the use of multi-spectrum technology.

Read more

In 1972, Ishida revolutionized the packaging industry by inventing computer combination weighing (CCW) technology. Ishida, the biggest name in weighing technology, offers the ultimate performance and delivers the top performing multihead weighing machines so their customers’ products are handled gently, cleanly, and efficiently.

Read more

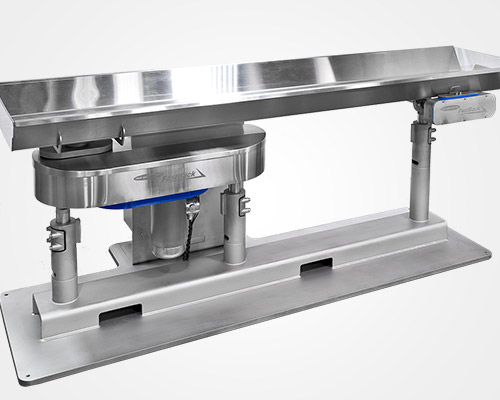

The FastBack® 4.0’s patented circular to linear motion design gently handles product so it is undamaged, and the coatings are undisturbed to provide the ultimate performance, flexibility, and highest travel rates and flow rate capacity in the industry.

Read more

The Ishida Inspira Snack Bagmaker (Inspira) is a vertical form fill sealing (VFFS) machine, an automated packaging system that fills and seals products in formed bags from roll stock. Inspira incorporates next generation snack packaging technology and offers a new level of automation and efficiency to consistently produce quality bags, dramatically increasing production efficiency for snack food manufacturers.

Read more