Cereal continues to be popular and the cereal industry is expected to experience more than a 4% compound annual growth rate for the next few years due to increasing demand from consumers’ busy schedules and improved flavor and nutritional quality. Many of our customers have been turning to our experts for decades to find equipment that handles product gently, weighs product accurately, and packages product securely, reducing waste and increasing their bottom line. Our cereal equipment can quickly and efficiently process a wide range of cereal types, regardless of the type of your product, and is of the highest quality, improving yields with reliable automated systems, reducing labor costs, and improving efficiency.

Tek-Dry Systems, a global leader in bespoke thermal processing solutions, delivers advanced drying, toasting, roasting, and cooling technologies for products ranging from French fries and snacks to cereals and pet food.

Read more

Conveyors are fast, efficient mechanical handling apparatuses that transport materials from point A to point B and play a critical role in advancing industry.

Read more

The growing market for nutraceuticals and functional foods leads to additional challenges for metal detection which can be solved through the use of multi-spectrum technology.

Read more

In 1972, Ishida revolutionized the packaging industry by inventing computer combination weighing (CCW) technology. Ishida, the biggest name in weighing technology, offers the ultimate performance and delivers the top performing multihead weighing machines so their customers’ products are handled gently, cleanly, and efficiently.

Read more

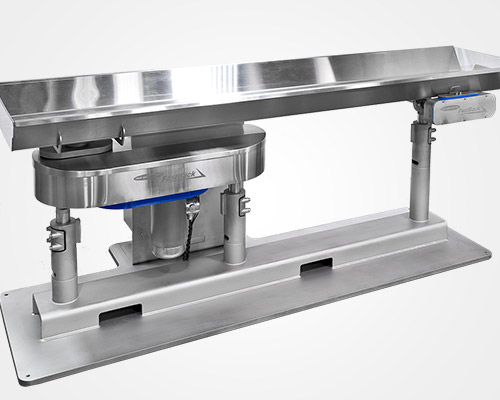

The FastBack® 4.0’s patented circular to linear motion design gently handles product so it is undamaged, and the coatings are undisturbed to provide the ultimate performance, flexibility, and highest travel rates and flow rate capacity in the industry.

Read more

Metal is one of the most commonly found contaminants in food and can be introduced at all stages of food manufacturing. By identifying metal contaminants during processing or packaging, a metal detector helps ensure the safety and the integrity of a wide range of unpackaged, packaged, or bulk goods and helps to eliminate metal contaminants from a food manufacturer’s finished product.

Read more

Checkweighers are designed to divert inferior product off the production line. Depending on a manufacturer’s product, Ishida provides several rejector arm options to optimize the checkweighing process.

Read more

Increases in product SKU are challenging for manufacturers who want to balance changing and increasing product variety with operational performance. Below is a Q&A with Todd Grube, Heat and Control Inspection Systems Product Manager, North America, on how different product types and sizes on the same line affect foreign object and quality control strategies.

Read more