Consumers appreciate the quality in the food they eat, and even though unable to say it, so do their pets.

Manufacturing dry pet food involves the same processes as many other processed foods. The most common application for coating of dry pet food kibble or pet treats involves applying sequential coatings of liquid fat/oil, followed by adding a liquid digest or palatant, and lastly, applying a powdered digest.

Because of the wide variety of products, there are multiple pet food coating system options, including continuous coating drum, centrifugal, gravity, blending, and screw feeder systems, depending on the manufacturer’s specific desired product characteristics.

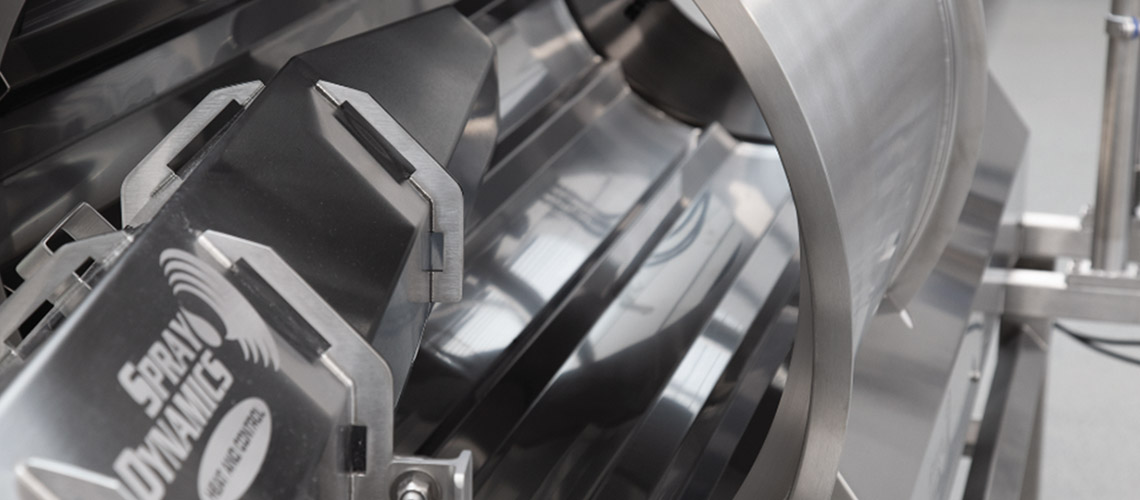

Heat and Control®’s Spray Dynamics® offers our innovative technology in continuous coating drum-based systems for pet food coating. Our system includes a coating drum, a liquid spray system, a powder metering, and a distribution system. Also, heated mix/use tank assemblies are often part of the supply scope.

Key principles for continuous drum-based coating are product residence time, product bed width consistency, and depth throughout the length of the drum. Another vital design principle is utilizing independent, expanded liquid and dry application zones. In this example there are four independent zones, one for each liquid product; a transition zone; and a dry ingredient application zone. These zones allow us to apply the liquid and dry additions at multiple points over a set distance of product travel rather than to introduce them at a single point of contact. When properly positioned above the base product as it travels through the drum, the coating of each product piece can match the correct amount of liquid and dry ingredients.

The size of the drum is determined by the amount of product to be coated, the product density, and the number of liquid and dry applications required. Drum diameters vary between 30–72" (76—183cm) in diameter and in lengths from 96–180" (244—457cm). Properly engineered coating drums feature horizontal product flights that are designed to gently lift and fold the product as the drum rotates. The drum operates at a slight decline towards discharge to allow the product to travel through the drum. An inlet cone directs the product into the coating drum cylinder and prevents spillage while a discharge spiral acts as a weir to help control the product bed and the dwell time.

An advantage of the coating drum method is its ability to control both product dwell time and product piece exposure. The lifting and folding of product throughout the length of the drum ensures each product piece is brought to the surface repeatedly for targeted application of the liquid and dry coatings. This method of exposure and expanded coating zone application is far more reliable than other drop-through coating methods that coat product falling vertically through a single point of contact then rely on a post blending process for product-to-product contact. The coating drum method ensures consistent, evenly coated product. Please note that optimally finish coated product requires a consistently metered flow of base product into the drum.

Continuous coating drum systems feature mist/dust collection shrouds or fully enclosed drums to prevent exposing plant personnel to the applied liquid and dry ingredients. An external collector is also part of the mitigation process. Clean-in-place foaming and spray bars are recommended for ease of sanitation at the end of the run.

As the kibble or treat enters the coating drum, the first of the two liquids, fat/oil is applied. Application rates typically vary between 2–10% by weight of base product throughput. Chicken fat is commonly used and heated to a range of 120–140°F (49–60°C) and usually done in a water or steam jacketed tank. A shaft mounted mixer is used for agitation. Once at temperature, the product is transferred to a use-tank that supplies product to the fat/oil spray manifold.

A positive displacement product supply pump is used to pull product from the heated supply tank and to transfer to the manifold. A three-way valve located at the manifold is used to supply the metered flow of fat to be applied. In addition, a liquid product flow meter is included for rate verification. When there is a pause or stop condition during production, the three-way valve diverts and continuously circulates fat through the loop until production resumes.

The fat/oil spray manifold features multiple spray nozzles in series with the first nozzle located ~8" (20cm) from the beginning of the drum. The length of the liquid coating zone varies depending on the size of the drum but is usually 24–36" (61–91cm) in length. The manifold is positioned at the proper height and angle to target the product traveling in the drum below, and air assist and positive shut-off nozzles generate the desired spray pattern. Using high-volume, low-pressure air avoids over atomization of the fat. Each nozzle produces an approximate 6–8" (15–20cm) diameter spray pattern, and the nozzles can be staggered and offset along the manifold for optimal coverage. Each nozzle includes an internal piston assembly that is used as a positive shut-off for standby or end of run conditions. Also, the piston functions as a cleanout mechanism to prevent build-up of liquid on the nozzle tip. A solenoid valve controls air on both sides of the piston head to regulate the piston actuation. The clean out cycle is done during the coating process, lasts only about one-quarter of a second, and does not interfere with the coating process.

After the liquid fat is applied, a second manifold positioned within the drum applies the liquid digest. Liquid digest application rates typically vary from 2–4% by weight of base product throughput. This product is also heated, to a range of 90–120°F (32–49°C). The manifold and the application process are identical to the liquid fat product described above.

The manifold assemblies are frequently mounted to pullout trolley assemblies for ease of sanitation.

After the liquid coatings have been applied, product travels through a short transition zone of about 18" (46cm). The transition zone separates the liquid coating process from the applied dry digest powder. The transition zone allows the base product to absorb the digest prior to dry coating. The dry powder or palatability enhancer is typically applied at 1.0–1.5% by weight of base product for canine products and 2–3% for feline products.

After the liquid coatings have been applied, product travels through a short transition zone of about 18" (46cm). The transition zone separates the liquid coating process from the applied dry digest powder. The transition zone allows the base product to absorb the digest prior to dry coating. The dry powder or palatability enhancer is typically applied at 1.0–1.5% by weight of base product for canine products and 2–3% for feline products.

The dry coating system consists of two pieces of equipment, an auger-based powder feeder and a scarf plate dry ingredient distributor. The powder feeder features a product supply hopper, an internal agitator assembly, a positive displacement auger, and a dispensing tube. The output of powder is determined by the speed and ratio of the motor and gearbox assembly. Depending on the layout, the powder feeder can be mounted to load cells for gravimetric control and verification of powders.

The powder feeder is positioned outside and perpendicular at the discharge end of the coating drum. The dispensing tube deposits product onto the inlet of the scarf plate distributor, a 6" (15cm) wide vibratory conveyor with a mirror finish and a bias-cut tray that extends into the coating drum. The metered digest powder travels down the length of the tray and passes over in an integrated weir that spreads the powder across the width of the tray. After the weir assembly, the powder transitions to the bias cut of the tray. As the tray tapers towards the discharge end, a curtain of digest is produced. This 24–48" (61—122cm) curtain (or dry coating zone) allows for a gradual application of the digest powder onto the liquid coated product below. The scarf plate distributor is frequently mounted to a pullout trolley assembly for ease of cleaning during sanitation. After the dry seasoning is applied, the finish coated product discharges from the coating system, ready for packaging.

Technical Sales Manager - North America