Gentle-Flo® Storage and Handling System

A modular, programmable, short-term storage solution for fresh produce capable of selective filling, auto-leveling, and variable speed discharge.

Gain access to all the equipment and expertise you need to efficiently transport, wash, peel, slice, and dice root vegetables—raw or cooked.

Years of experience with potato and vegetable processing around the world have informed the smart design of our solutions.

Smooth and continuous bulk processing capabilities enable high-volume capacity and a steady flow to downstream equipment, while reducing downtime.

Built for decades of operation and low lifecycle costs, our root vegetable product processors consistently maintain high performance production.

A modular, programmable, short-term storage solution for fresh produce capable of selective filling, auto-leveling, and variable speed discharge.

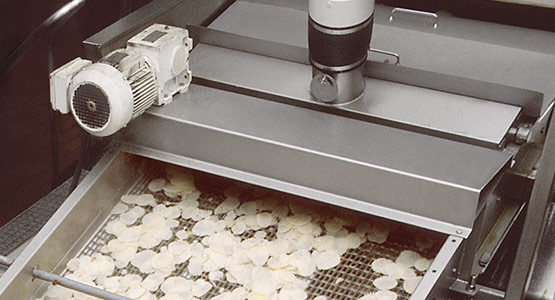

The space-saving FastLane combines the gentle horizontal motion of the FastBack Model 260E-G3 with a multi-lane pan that singulates product for delivery into multiple rotary slicers, reducing slicer overload and improving slice quality.

Versatile design provides controlled washing or blanching of potato slices. Choose from hot water blanching or cold water washing to maintain consistent chip quality when using different grades of potatoes.

The turbulent water bath with fresh water sprays provides more extensive starch and scrap removal than other models and quickly rinses surface starch and particles from potato slices for uniformly finished chips and cleaner fryer operation. This model can also be modified for banana and plantain slices.

This 3-stage potato slice washer removes surface starch and fines while cleaning and reusing wash water. Comprised of individual easy-to-install modules, Gentle Wash can be configured to fit into existing lines and uses minimal floor space.

The system combines vacuum action with our Air Knife’s blow-off forces to quickly remove surface water, starch, and scraps from just-washed potato slices, fruits, vegetables, and other products before frying or freezing.

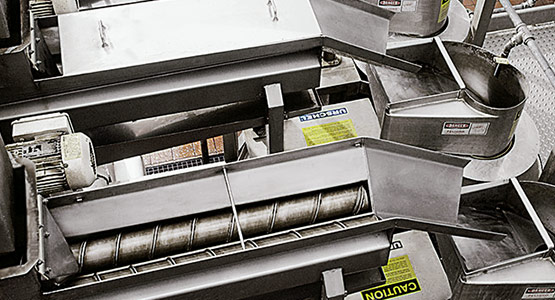

This large-diameter variable-speed auger quickly elevates your product to peelers or to other equipment while separating it from rocks and other debris.

Grade-level hydraulic lift system can tilt 70-foot long truck trailers to empty product for transfer to processing or to storage equipment.

Improve potato slicing quality and reduces scrap and fines generation by feeding potatoes single-file into slicers.

A rugged and reliable system that meters crated produce such as potatoes and vegetables in a consistent flow to other processing equipment.

Manual inspection, defect removal and trimming of potatoes and other vegetables is easy with this inspection conveyor.

Safely tilt crates of potatoes, onions, and other produce into a metering hopper. This rugged, reliable system will help provide a consistent flow to processing equipment.

Remove excess surface water from wet, just-washed products. Producing two high velocity air curtains across the width of your conveyor or washer discharge, the Air Knife lifts and separates product to remove surface water, starch, and particles.

Consistent potato chip frying, seasoning, and packaging all depend on how evenly potatoes enter your system. The Slicer Feeder provides a continuous and uniform flow of potatoes to the slicer for maximum slicing efficiency and less waste.

A cost-effective solution designed to consistently grade potatoes according to size then halve any that are larger than the predetermined size. Operators can easily adjust the grading size at any time during the production process and can also adjust the minimal size before rejecting very small potatoes, as well as foreign objects.

Quickly peel and wash a continuous high-capacity flow of potatoes and other root crops. Abrasive rollers quickly remove peel while a water spray rinses away loose peel and debris, preventing build-ups in the peeler and downstream equipment.