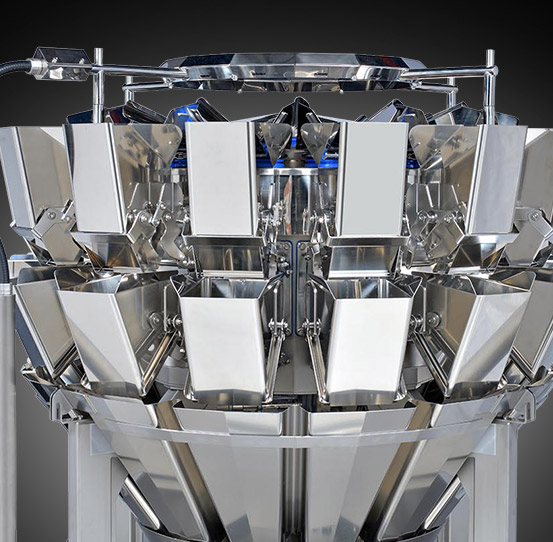

Inspection

Gain product safety and quality control confidence with CEIA metal detection

CEIA metal detectors deliver unparalleled inspection with extremely high detection sensitivity for metals. We'll have a broad range of metal detection equipment at our booth including the next evolution of CEIA metal detection systems being introduced for the first time at Pack Expo Las Vegas.