Spray Dynamics

Two-Stage Coating System

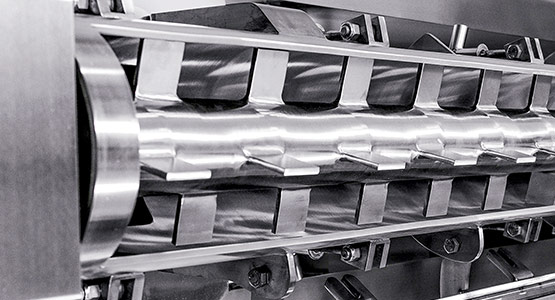

The Spray Dynamics Two-Stage Coating System provides consistent, uniform application of liquid and dry coatings to a variety of product applications.

The Spray Dynamics Two-Stage Coating System provides consistent, uniform application of liquid and dry coatings to a variety of product applications.

Isolating the mixing process in separate mix and use tanks improves the consistency of the blended product. The entire tank system can be heated or chilled and can be located on a skid making it self-contained and easy to handle.

The Spray Dynamics MS II is designed for accurate and reliable over-the-belt or top-and-bottom delivery of liquid coatings on oven bands, dehydrator belts, and in-pan and cavity applications. This system accurately meters and sprays oils, antioxidants, vitamins, flavors, tack, release agents, and other liquid coatings.

A user-friendly spray system providing continuous, metered "airless" oil application using our patented two-hole nozzle design that delivers a fan shaped spray pattern for optimal product coating. The Spray Dynamics MS III is designed for use with our coating drum, blender, belt, or auger systems.

Designed specifically for pure or flavored oil applications, continuously spray oil with cone-shaped spray pattern at each nozzle inside a coating drum, in a blender, or across a belt where finer droplet size is needed.

Spray virtually any pumpable slurry, including sugar, syrup, chocolate, oil, or emulsion to maximize coverage and to minimize waste. This Spray Dynamics slurry spray system is engineered for cereal, snack, and pet food applications for use in coating drum and conveyor belt systems.

The recipe-driven, tankless, continuous mixer automatically and accurately mixes seasonings and liquids into homogeneous, lump-free slurries in the desired quantity demanded downstream, significantly reducing wasted ingredients and operator start-up and cleaning time. It eliminates the inherent flaws of standard mix and use tank systems.

Our automatic Belt Coater quickly and uniformly applies chocolate, yogurt, and sugar solutions to nuts, fruits, candy cores, cereals, and other products.

The Spray Dynamics MS I offers a complete gravity fed, pulse-operating spray system, designed for accurate and reliable application of liquid coatings inside a coating drum. This system accurately meters and sprays oils, antioxidants, vitamins, flavors, tack, release agents, and other liquid coatings.