A leading manufacturer of gummi confectionery, marshmallows, liquorice, hard candies and bubble gum achieves packaging room success with Ishida’s comprehensive range of multihead weighing technology. The company has 12 Ishida multihead weighers, responsible for weighing many different varieties of confectionery.

Chewing gum, a relatively fragile product, can be difficult to handle. Chewing gum begins to lose moisture as soon as it’s made, which means that harsh treatment could easily cause pieces of the outer coating to break off. Fast, accurate packing machinery is essential for efficient production at such small pack sizes, so they selected an Ishida weigher with bancollan linings to reduce impact damage and the force of collisions. A 16-head double outlet model was selected to fill resealable doypacks with chewing gum pieces. It fills 6.3oz (180g), 5oz (142g) and smaller packs of 28 pieces per pack, at 120 packs per minute (60ppm each side).

Chewy jellies come in a huge variety of shapes and sizes. For weighing and packing purposes, they fall into two main categories. On separation from their molds, the jellies can be oiled, to give a shine, or sugar-sanded for a more traditional look.

Sugared jellies are relatively easy to handle and is weighed by 16-head double discharge multihead weighers, the small footprint allows for two fast weighers into the space of one larger one. They’re very flexible and offers operational efficiency, while one is running the other can be cleaned.

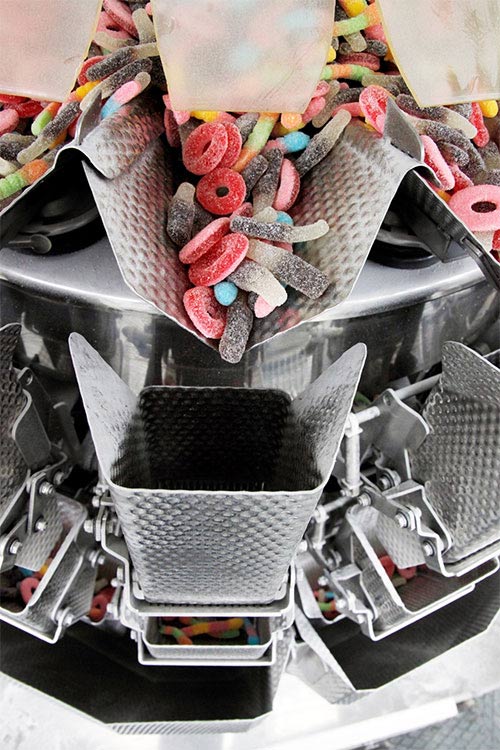

Oiled jellies are much more inclined to stick, especially in the case of products such as ‘fried eggs’ or ‘rings’, where there are relatively large flat surfaces. In this situation one weigher is dedicated to each product, the number of heads helps to make up for a relatively slow-moving product.

Glazed liquorice is comparable to oiled jelly in stickiness. Mixtures of liquorice candies are also weighed on 14-head weighers with special contact parts. Among the weighers used for the oiled jellies are single-discharge 14-head weighers with anti-stick contact parts, including metal mesh in the hopper gates.

Marshmallows, dusted with sugar or corn flour, are handled on a 16-head double discharge weigher mounted over twin bagmakers, filling 17.6oz (500g) and 2lb,12oz (1.25kg) bags. The weigher has spacious 6.3-gal (3L) hoppers to accommodate this bulky product.