Conveyor belts take a beating on hard-working breading applicators. Constructed of thin wire and subjected to long hours of operation, multiple turns, varying loads, and high stresses, these conveyor belts traditionally have a short lifespan. However after installing new Heat and Control breading applicators, Brakebush Brothers, Inc. (Westfield, WI) reports belt life has greatly improved.

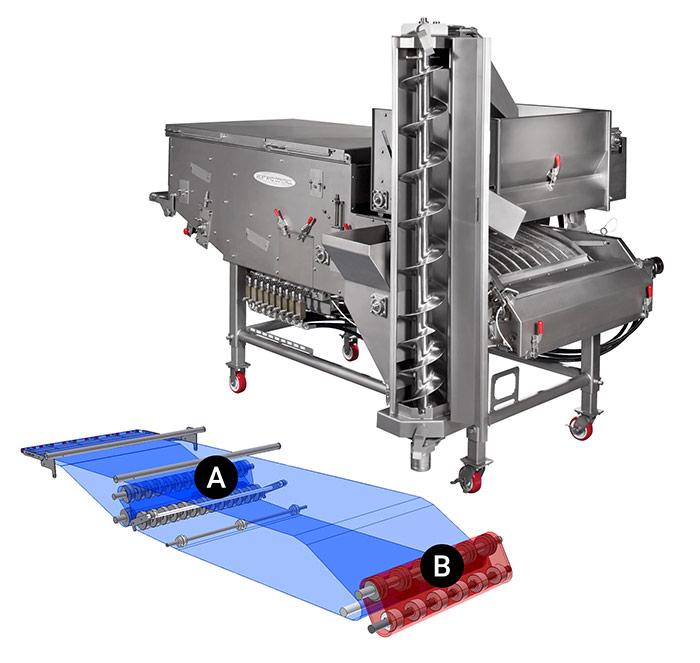

Founded in 1925, Brakebush is a leading processor of chicken tenders, strips, formed nuggets, and patties for retail, foodservice and deli outlets. In order to improve uptime, Brakebush installed a new coating line from Heat and Control on a fully cooked chicken production line. The new line included a SureCoat Breading Applicator equipped with an automatic belt tensioning system. In addition to maintaining consistent belt life, the system has boosted productivity at Brakebush Brothers.

"Based on our maintenance records, we have increased belt life to 8 months since switching to the SureCoat breaders," explains the Process Improvement Manager. "We run our breading applicators up to 16 consecutive hours each day. Any time a breader belt fails the entire line must be shut down for belt replacement, and that quickly gets very expensive," he explains. "Longer belt life is a big improvement, and the SureCoat breaders have proved to be reliable and durable."

Brakebush was so pleased with the equipment, they installed another coating line. "We've standardized on Heat and Control breading applicators because they are robust and easy to operate, and they also have a lifter conveyor that lets you adjust the breading bed density and prevents break-off jams (breading jams at the infeed end)".

"We run flour, crumbs and J-crumbs on the same breader and its operation with all coatings is excellent. We are also very pleased with the service and support provided by Heat and Control".

Automatic tensioning (A) increases conveyor belt life. Breading bed density can be adjusted for different products by varying Lifter Conveyor (B) speed.