Product Finder

Find our industry leading equipment by name or product category.

Products by Brand

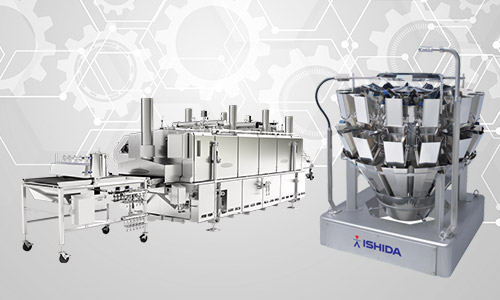

We offer a broad range of solutions through our equipment brands and partners, each with specialists that have extensive insight and experience.

New Products

Explore our latest innovations and technologies to help your company achieve a new level of success.