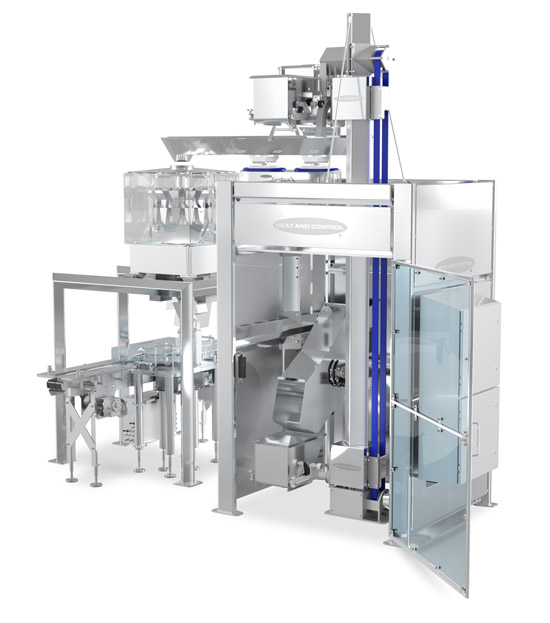

Potato Unloading & Storage

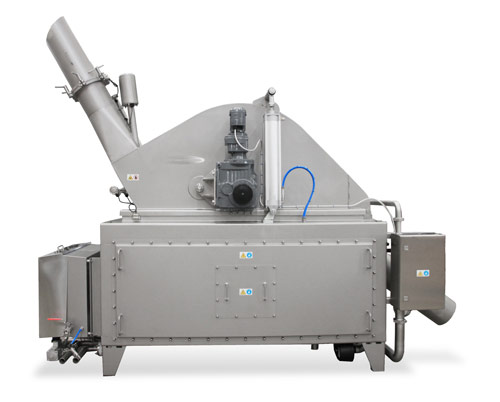

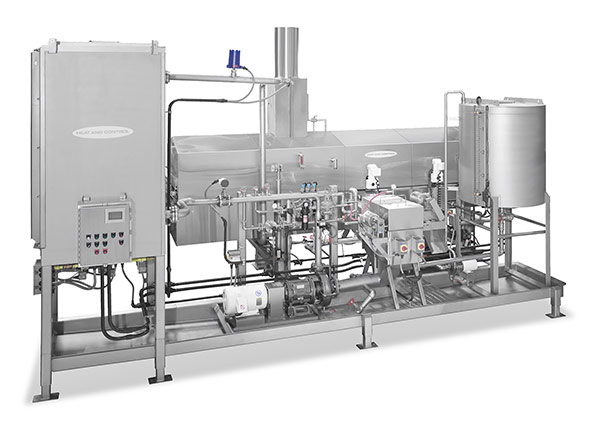

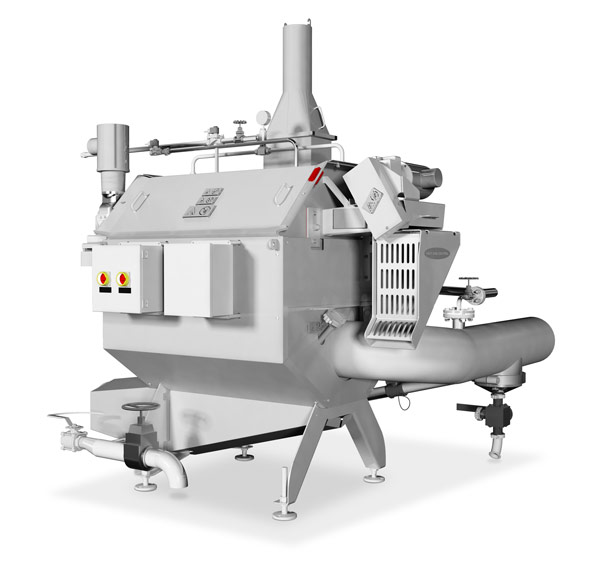

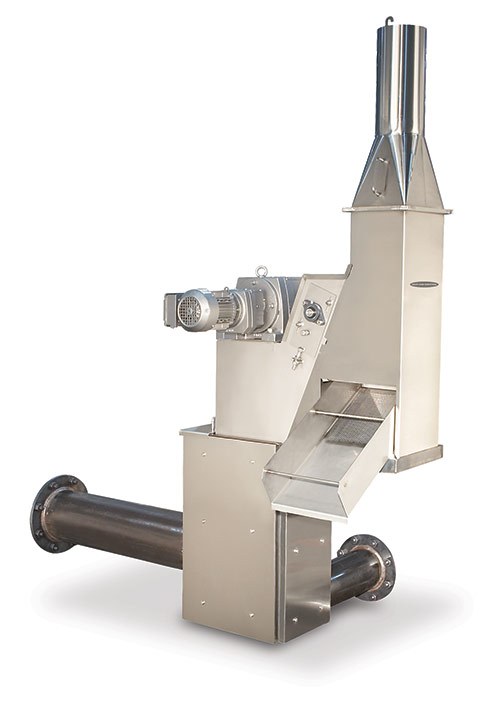

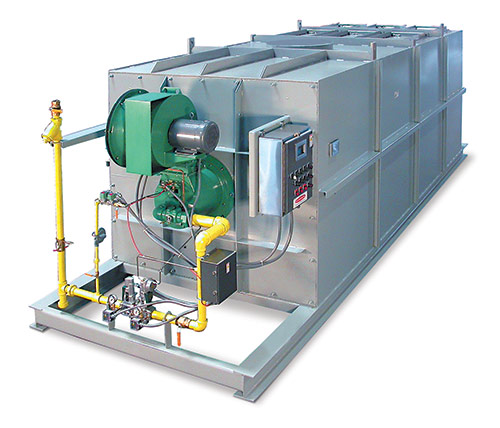

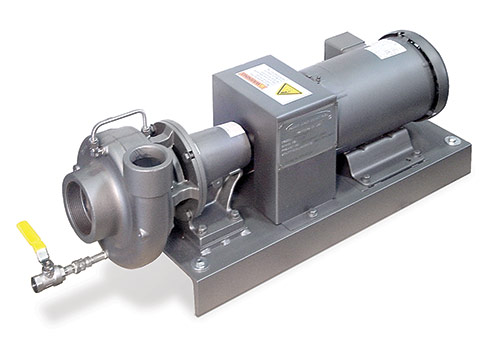

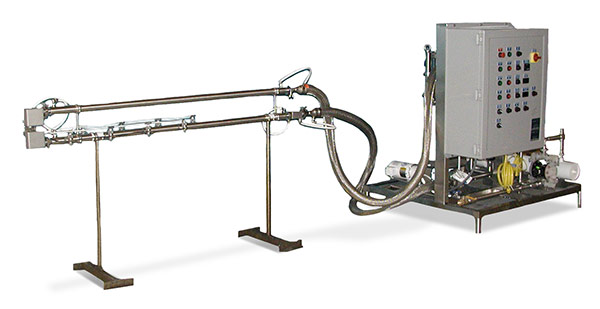

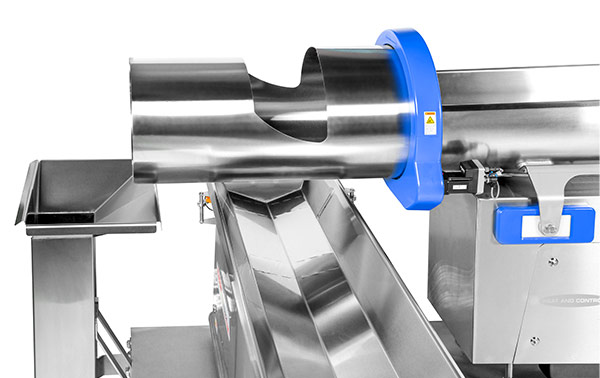

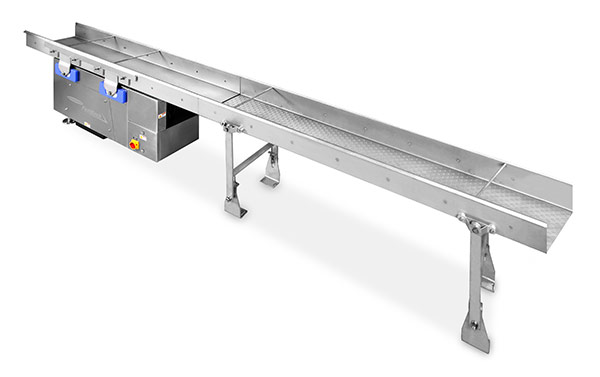

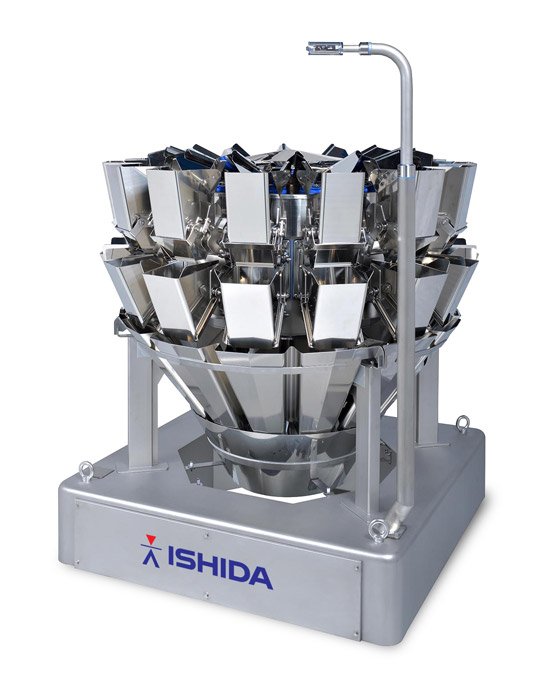

Raw potato handling is simplified as it enters the facility with equipment to unload and store potatoes prior to processing. Truck dumpers, dirt removers, transfer, and bin storage systems handle large volumes of potatoes easily and gently. Working with our strategic partners, we are capable of full receiving area solutions.